Two Cases for Large-Span Corrugated Steel Plate Structure

This project located in a tourist area in Handan city, Hebei province. The specification of this bridge as below

Span: 15.3m

Height: 10.6m

Corrugation: 380*140mm

Steel Plate Thickness: 9.0mm

Bridge Width: 9m

The cross-section of the structure is horseshoe-shaped, with specification of narrow at the top and wide at the bottom, it has unique advantages for passage engineering, but the force of the arch toe is relatively unfavorable, requiring strict force analysis and special structural measures.

10m Diameter Multi-Plate People Tunnel

In Guangdong has a township road-179, the road width is 5m, the original design is to set a middle bridge with 25meter length, the net width under the bridge is about 9m, the township road is changed to pass under the bridge, then change the road width to 7m. The township road is an important passage connecting three larger natural villages (with a permanent population of about 18,000). The local people reported that the original design road change could not meet the local travel requirements. After many consultations with the local government, for long-term considerations, a channel with a diameter of not less than 1-8*5.5m should be added to the original road, and it is recommended to choose a plan, with a shorter construction period and complete the construction as soon as possible, to maximize to minimize the resistance of local people and maintain social stability, it was decided to adopt a 10m diameter steel pipe channel scheme after comprehensive consideration.

The angle between the steel corrugated pipe channel and the route is 42°, the culvert length is 120.68m (including the steel corrugated pipe at the entrance of the tunnel). The entrance and exit of the culvert are bamboo-cut + eight-character walls, and the culvert serves as drainage. In order to reduce the length of the culvert and increase the brightness in the cave, The subgrade slope rate was adjusted according to the review opinions of the plan. The primary slope rate was adjusted from 1:1.5 to 1:1, and the secondary slope was adjusted from 1:1.75 to 1:1.5, and the secondary platform was cancelled. The steel-plastic grille is added in the subgrade to minimize the length of the culvert while ensuring the overall stability of the subgrade.

For the calculation of the bellows, the ultimate load method is used to calculate the structure, and the soil weight is calculated according to the theory of soil column weight. The live load does not consider the friction between the top soil column and the surrounding fill. The angle distribution method is used for calculation, semi-infinite elastic body Theoretical accounting.

The wall thickness of the corrugated steel culvert is designed in sections according to the different filling heights. The wall thickness chooses 8mm at of the hole and the lower filling party, and the wall thickness choose 10mm at the party of the middle filling.

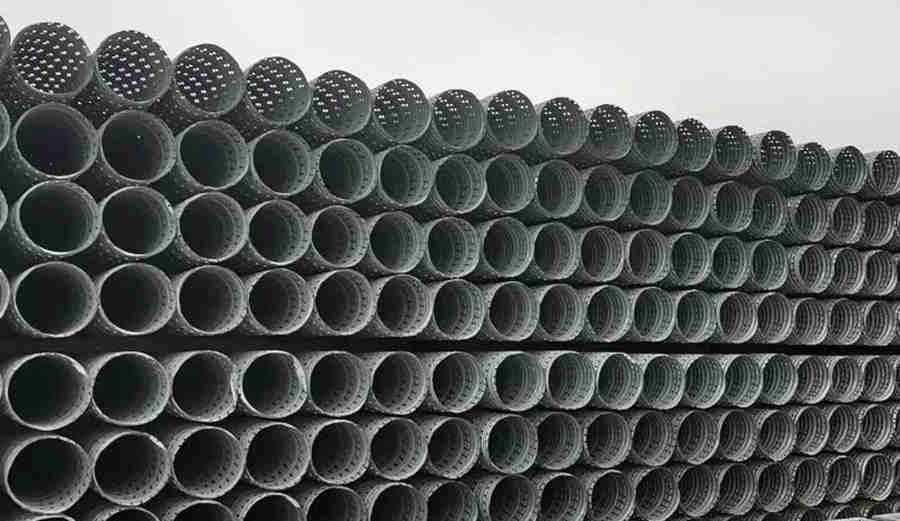

The corrugated size of steel corrugated pipe is 400×150mm. The culvert pipe adopts the installation method of outer ring and inner ring, and the inner and outer rings are assembly by 6 corrugated plates.